Product Breakdown - What does it take to design an Electronic Product?

Breaking down a infotainment system's remote and looking at all the aspects of engineering that went into designing it

Recently, I was travelling from US to India. Stuck in a 22 hour long flight with no internet surely makes you think; think what all did it take to design the simple controller for in flight entertainment in front of me. Thinking about all the aspects of engineering that went into this designing and manufacturing this product, I started to list them down. To make it more graphic and understandable, I ordered a similar product to break it down and actually reverse engineer it. Let’s take a look.

Let’s look at the exploded view of the remote. Each field marked up in yellow is a niche engineering field in itself with a team of engineers working specifically on that. Along with the technical aspects, there are a ton of resources that goes into defining the product requirements, doing a business analysis, figuring out the logistics and shipments, packaging, supply chain, costs, finances of the product. All, so that you can buy this piece in less than $15 shipped which in itself is a marvel.

Opening the product out it majorly consists of

- Mechanical Enclosure

- Buttons

- Circuit Board (Printed Circuit Board aka PCB)

- Battery

To be fair, I’m no expert in most of these fields. I just am aware of them, I can probably only do justice to aspects of circuit board development and mention the other fields to the best of my knowledge. I’ll get to circuit board at the end after touching up on other aspects of the product.

Mechanical Enclosure

Starting with the mechanical enclosure, a group of engineers first did material engineering to select most cost effective, durable, easy to work with material to be used in the project. Another group of engineers did 3D modelling on how the remote should look and feel like keeping in mind the ergonomics of handling it, weight, space to actually accommodate the circuit board. Then another group of engineers worked on how this thing would be actually manufactured in the most cost effective way depending on the volume i.e. injection molding, designing tools, molds and manufacturing line for the same. That just cover a part of engineering that went into designing the enclosure which I’m aware about.

Rubber Keypad

When it comes to the rubber keyboard, I have almost no knowledge there. But for appreciation of the field, I found this article webpage just glancing at which is enough to appreciate the number of variables in even something this simple looking. https://www.rubber-keypad.com/Silicone-Keypad-Design-Guide.html

Battery

Battery, a lot of chemical engineering and material science went into finding and designing the group of material which can store, charge and discharge energy safely into the circuit.

Circuit Board

Now to the field which I can actually do a bit of justice to, circuit board designing.

It starts with architecting and selecting the proper set of components. Each component specially chips or IC designing takes multiple years and revision and investment to even get the simplest thing out. I’m not remotely capable of making you understand the intricate details of the process in an article, but take a look at the couple of videos in the last section to understand the process.

Next, various sections of circuits are designed. Each circuit needs specialists working in a particular field. In this board, there are 5 particular sections.

- Power Management - Designing and converting the power received from battery so that it can be used by rest of the circuit. Also calculating battery life, charging circuits to safely operate the devices.

- Sensor Design - Selecting the sensor based on what kind of inputs are to be detected. In this case, accelerometer to find if the remote has been moved in air to change the position of mouse on the screen

- Microcontroller - AKA brain of the system which looks at which button has been pressed, reads the sensor to see what action has been performed. Then translates the button to something that can be understood by computer and sends it to the Bluetooth module. Microcontroller also takes care of LEDs to be lit up, signals to be sent via infrared to the TV and all of this is written in software (firmware) and programmed into the controller.

- Wireless Communication and antenna design - Deciding the communication language which will be understood by both computer and the remote, encoding signals in invisible microwaves operating at particular frequency band, decoding the waves to find what signals were transmitted and what do they even mean. Designing antenna which can help transmit and receive these signals in such a fashion that they do not interfere with other electronics in the vicinity.

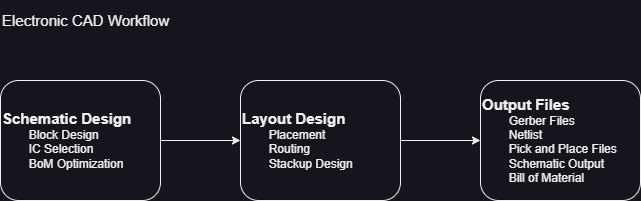

- Electronic CAD Design - Taking the inputs from various blocks and integrating it into drawings using software which can be understood by other engineers and manufactured. The team outputs various files needed by different teams who will work on procuring the material, manufacturing the circuit board, testing it, engineers who’ll need to understand it to solve problems in future.

Post design and development comes manufacturing which is a BEAST. Finely tuned machines and humans working in unison to create a product intricate and sophisticated all for a couple of bucks.

Right from wires, enclosure, batteries, fasteners, Semiconductors and circuit boards. Each thing takes number of processes and steps to be manufactured. I’ll list down some of the videos for the field.

Manufacturing

Circuit Boards

Semiconductors

Injection Molding

Wires

Batteries

Hope this makes you appreciate the amount of effort that goes into a designing a simple product. Again, this article is only the tip of iceberg for the actual effort spent if you see these product from scratch. I didn’t even touch on various aspects like passives, fasteners, adhesives etc. which plays very important role in making the device work as well.

The exercise of reverse engineering and studying the remote raise more questions, learnings and appreciation for me which I hope to cover in future article. If someone is interested in finding answers to some of these questions and collaborating for a future article, ping me on LinkedIn. Curious about another object? Let me know and I’ll consider it for a future article.

Until next time, look around and stay curious.

Thanks for reading Rishabh’s Substack! Subscribe for free to receive new posts and support my work.